Enhancing Workforce Cyber Resilience

Enhancing Workforce Cyber Resilience

Collaborators: Drs. Husnu S. Narman and Paulus Wahjudi

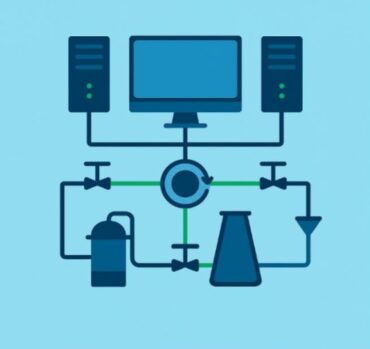

Abstract: This study addresses the cybersecurity challenges facing Industrial Control Systems (ICS) by bridging the expertise gap between ICS Engineers and IT/Cybersecurity Specialists. It reviews recent attacks, training deficiencies, and emerging educational strategies—such as gamification, simulation, and AI-enhanced learning. A case study at Marshall University using CyberHive simulation demonstrated improved student performance and accuracy in cybersecurity challenges. The study advocates for integrated, hands-on training to build a resilient workforce capable of defending critical infrastructure, emphasizing cross-disciplinary collaboration and adaptive learning environments.

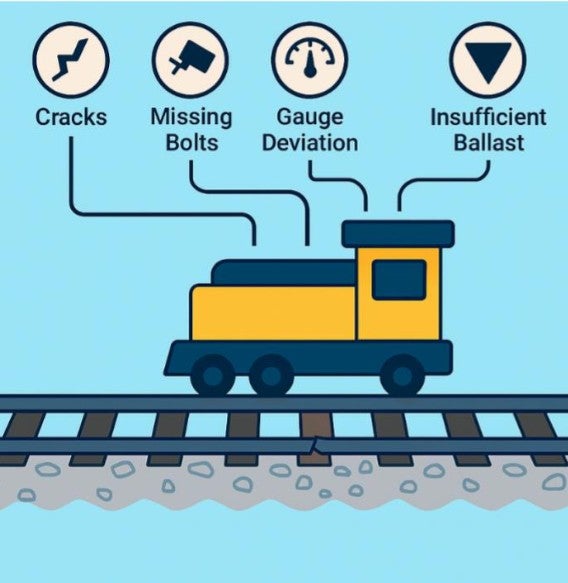

Solidifying America’s Railway Infrastructure

Solidifying America’s Railway Infrastructure

Collaborators: Drs. Husnu S. Narman, Ammar Alzarrad, and Pingping Zhu

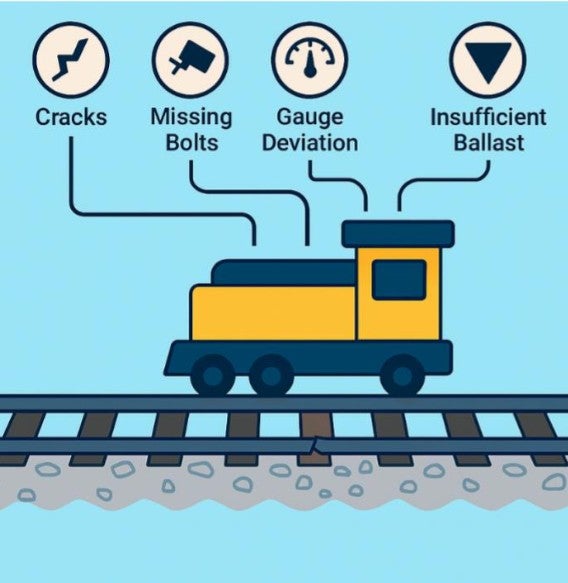

Abstract: This study explores the use of deep learning to automate railway track defect defection, focusing on issues such as vegetation, cracks, missing bolts, gauge deviation, and insufficient ballast. By evaluating various machine learning models, the research identifies several ML models such as YOLOv5 and YOLOv9, achieving high accuracy in multi-class classification tasks. The models were trained on diverse datasets and assessed using precision, recall, and F1-scores. Explainable AI techniques were employed to interpret model decisions. The findings highlight the potential of AI to enhance railway safety, reduce inspection costs, and support proactive maintenance through accurate, real-time defect identification.

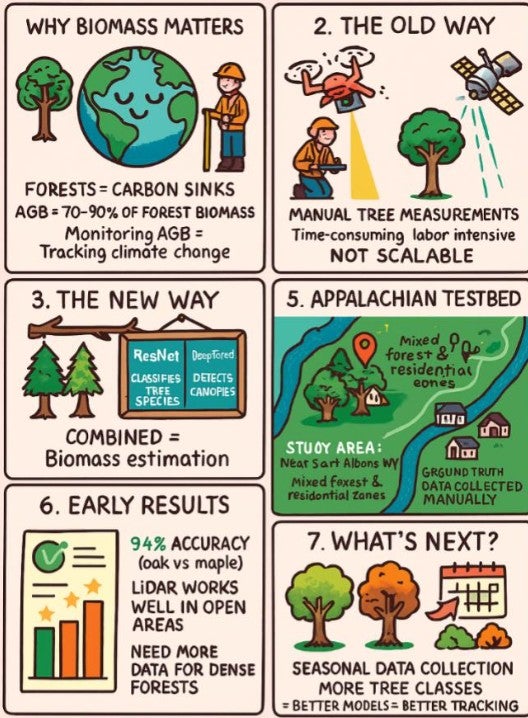

Remote Estimation of Above Ground Forest Biomass

Remote Estimation of Above Ground Forest Biomass

Collaborators: Drs. Husnu S. Narman and Rick Gage

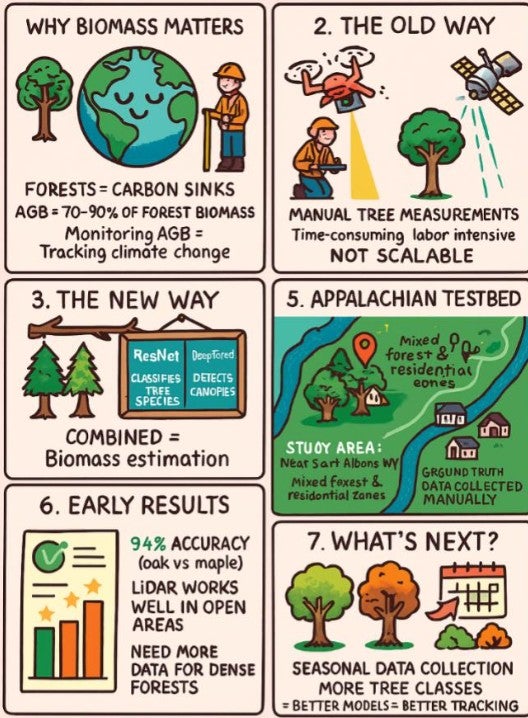

Abstract: This study explores a modern approach to estimating forest biomass using drone imagery, satellite LiDAR, and machine learning. Traditional biomass measurement methods are labor-intensive and slow, prompting the need for scalable, remote techniques. Researchers developed models to identify tree species and estimate biomass based on canopy size and height, even in areas with limited ground-truth data. Early results show promise, especially in open forest regions, though more data is needed for dense environments. The project highlights the potential of combining accessible technologies with AI to monitor forest health and carbon stocks, contributing to climate change research and environmental management.

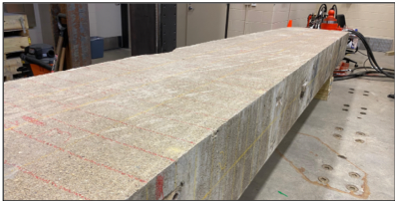

Enhancing Bridges’ Structural Integrity Assessment Through Non-Destructive Evaluation

Enhancing Bridges’ Structural Integrity Assessment Through Non-Destructive Evaluation

Dr. Wael Zatar

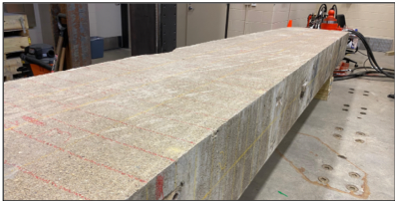

Short Summary: This study presents a nondestructive testing method using ground-penetrating radar to estimate rebar diameters in concrete. By applying normalized amplitude-diameter-depth relationships that link wave amplitude to bar size and depth while minimizing signal and coupling effects, the model—developed from slab data and validated on bridge beams—achieved high accuracy, offering a reliable quantitative tool for assessing reinforcement in concrete structures.

Implementing Lifecycle Characterization of Embedded Dam Gate Anchorage Using Non-Destructive Testing and Structural Health Monitoring

Implementing Lifecycle Characterization of Embedded Dam Gate Anchorage Using Non-Destructive Testing and Structural Health Monitoring

Dr. Wael Zatar

Short summary: Dams across the U.S. are vital for flood control, navigation, and power generation, with Tainter gates supported by trunnion anchor rods that can deteriorate and pose safety risks. Research developed a lifecycle framework to enhance the reliability and longevity of these components by identifying key degradation factors and using nondestructive testing to refine models and guide maintenance, helping dam owners ensure long-term safety.

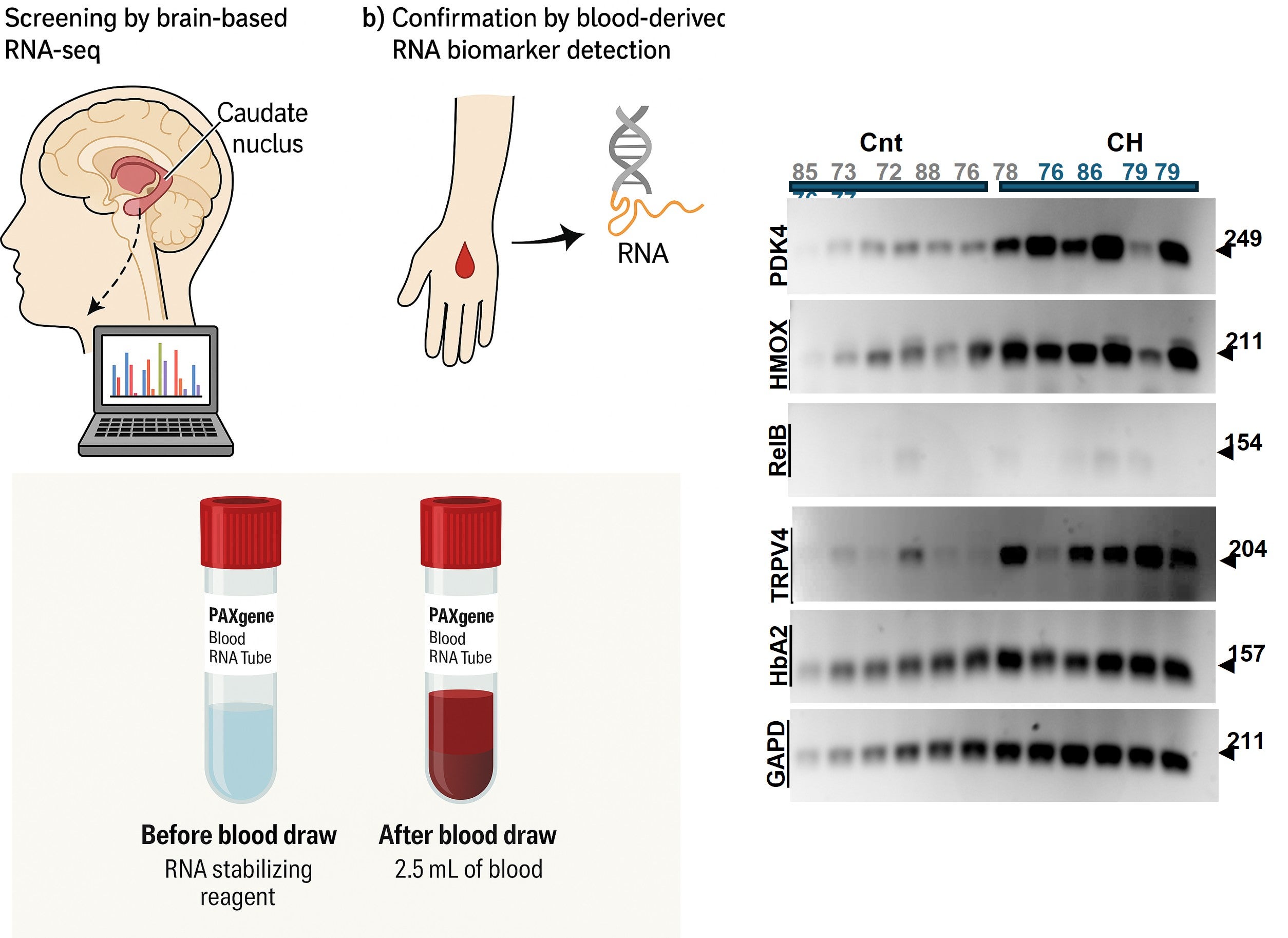

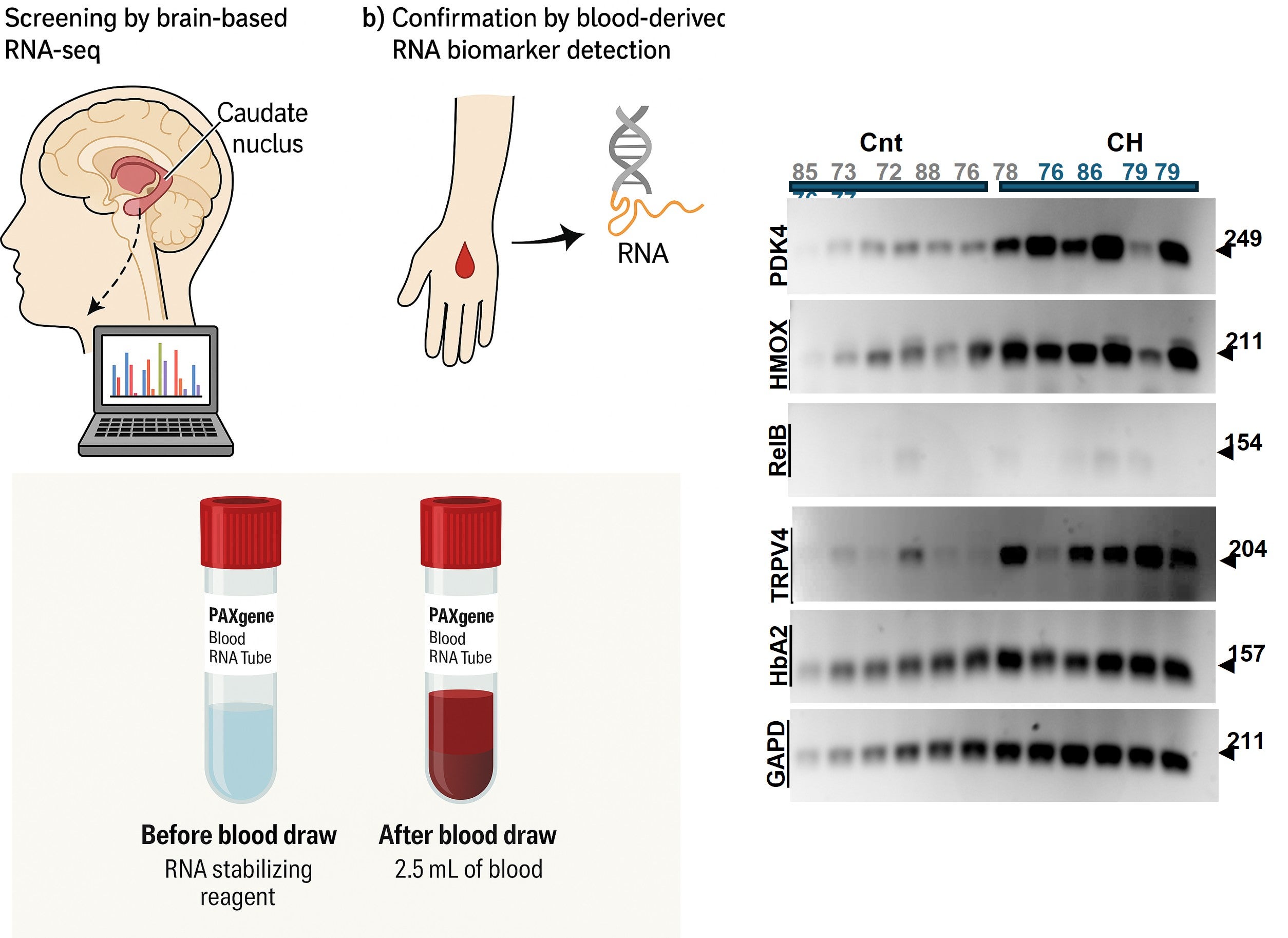

Blood-Based RNA Biomarkers of Alzheimer’s Disease and Related Dementia

Blood-Based RNA Biomarkers of Alzheimer’s Disease and Related Dementia

Collaborators: Drs. Joon W. “Simon” Shim, Courtney Wellman, and Todd Davies

Abstract: Dr. Joon W. “Simon” Shim’s research investigates blood-based RNA biomarkers that can enable early and noninvasive detection of Alzheimer’s disease (AD) and Parkinson’s disease dementia (PDD). Building on recent discoveries from postmortem brain transcriptomic analyses, his team found that hemoglobin genes (HBA1, HBB) are significantly reduced in Alzheimer’s and Parkinson’s tissues, suggesting a novel link between impaired oxygen transport, hypoxia, and cognitive decline.

The project aims to determine whether these brain-specific RNA changes are also detectable in peripheral blood of living patients and to examine how they relate to systemic oxygen saturation. Using quantitative RT-PCR and pulse co-oximetry, the study will analyze blood samples from patients with AD, PDD, and cognitively normal controls.

This research bridges biomedical engineering, neuroscience, and geriatric medicine to identify molecular signatures that reflect both neural and systemic health. If successful, the findings could lead to accessible diagnostic tools for early detection and personalized intervention—such as oxygen-based therapies—to slow or prevent cognitive decline in aging populations.

Multi Projects

Multi Projects

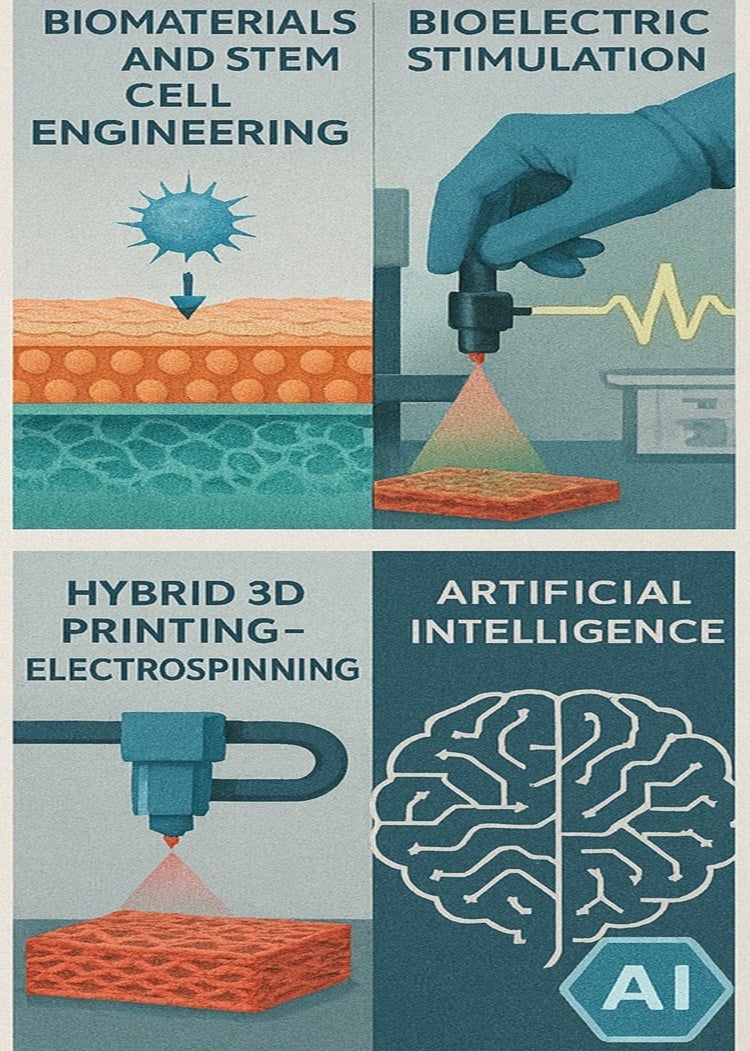

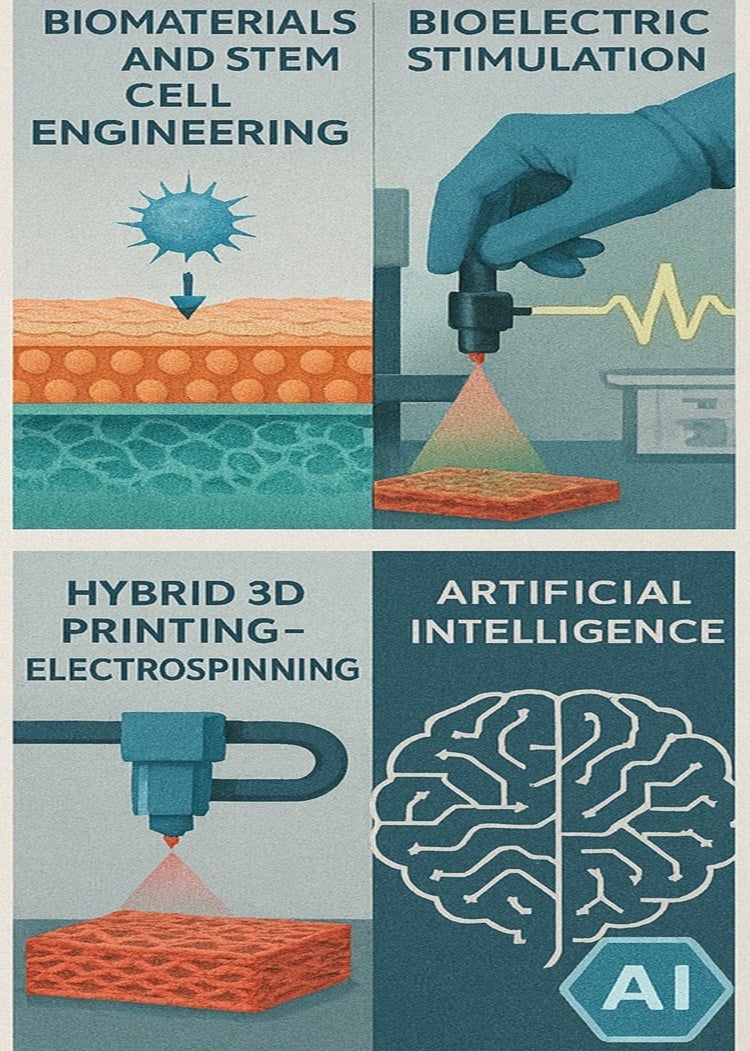

Dr. Nasim Nosoudi

Dr. Nasim Nosoudi’s research integrates biomaterials, stem cell engineering, and bioelectric stimulation to create next-generation regenerative platforms. Her work focuses on electrospinning and electrospraying technologies to control stem cell fate and engineer biomimetic scaffolds that promote tissue repair and regeneration.

She also leads several complementary research projects, including the fabrication of cotton-based nanofibers as biodegradable scaffolds, the development of hybrid 3D printing–electrospinning systems for creating multilayered ECM-mimicking structures, and the integration of artificial intelligence for predictive modeling in healthcare.

Dr. Nosoudi’s program is supported by multiple competitive awards, including:

· NSF CAREER Award (Award #2337961, 2024–2029): “Exploring the Differentiation of Mesenchymal Stem Cells to Chondrocytes After Electrospraying” ~$604,000.

· NSF MRI Awards.

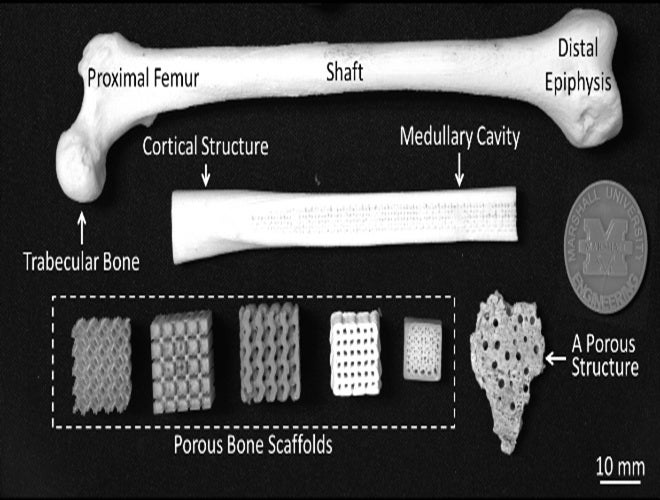

Implant Fabrication Using Advanced Manufacturing Techniques for Bone Tissue Engineering

Implant Fabrication Using Advanced Manufacturing Techniques for Bone Tissue Engineering

Dr. Ross Salary

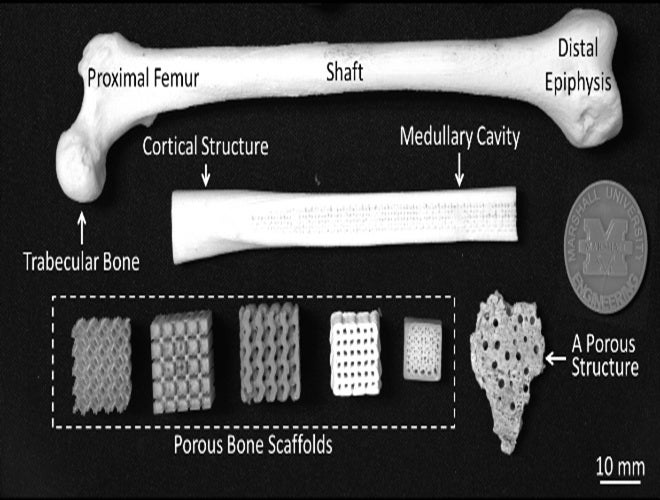

This project is supported by the National Aeronautics & Space Administration (NASA) under Award Numbers 80NSSC22M0249 and 80NSSC19M0054, focuses on implant fabrication using advanced manufacturing techniques for bone tissue engineering in collaboration with the School of Medicine at Marshall University. This multidisciplinary project integrates mechanical engineering, biomedical science, and artificial intelligence (AI) principles to address one of the most pressing challenges in regenerative medicine, i.e., designing and fabricating patient-specific bone implants that can effectively support and stimulate tissue regeneration. The research problem at the core of this project arises from the complex and interdependent influences of material, process, and biological factors on implant performance. Despite significant advancements in scaffold design and fabrication, it has remained largely unknown how these factors collectively determine the structural integrity, mechanical functionality, and osteogenic (bone-forming) potential of the resulting implants. Variations in material composition, fabrication parameters, pore geometry, and cell-related factors can significantly impact the biological response, potentially leading to inconsistencies in bone growth and integration. Therefore, there is a need to identify the fundamental mechanisms and underlying relationships that govern scaffold fabrication, osteogenesis (bone formation), and ultimately, the fracture-healing process. By identifying and investigating these relationships through experimental characterization and computational modeling, this project aims to establish predictive frameworks and design principles that enable the fabrication of patient-specific bone implants. The outcomes of this project are expected to advance the frontier of bioprinting technologies and contribute to the development of self-healing and clinically viable bone implants that improve recovery outcomes for patients with complex injuries or defects

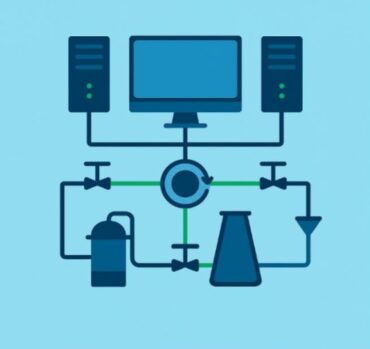

The Investigation of Aerosol Formation, Transport, and Deposition in (AJP) for High-Resolution Fabrication of Electronic Devices

The Investigation of Aerosol Formation, Transport, and Deposition in (AJP) for High-Resolution Fabrication of Electronic Devices

Dr. Ross Salary

This project is supported by the National Science Foundation (NSF) under Award Number OIA-2327460 and by the National Aeronautics & Space Administration (NASA) under Award Number 80NSSC24K0607, focuses on the investigation of aerosol formation, transport, and deposition in aerosol jet printing (AJP) for high-resolution fabrication of electronic devices. AJP is a direct-write additive manufacturing technique that enables maskless, non-contact fabrication of a broad spectrum of electronics, including sensors, transistors, antennas, and optoelectronic devices, on both planar and three-dimensional surfaces. Despite these advantages, AJP is highly complex and sensitive to subtle variations in process conditions. AJP often suffers from gradual drifts in aerosol transport and deposition, resulting in inconsistencies and defects that compromise the dimensional accuracy and functional performance of printed electronic devices. Therefore, there is a need to identify and characterize the underlying aerodynamic phenomena that govern aerosol flow dynamics in AJP. This project aims to uncover and elucidate the key mechanisms behind aerosol generation, transport, and deposition in AJP through computational fluid dynamics (CFD) modeling, experimental validation, and AI-driven modeling. Overall, this project will enable high-resolution, defect-free fabrication of electronics, advancing precision, reliability, and miniaturization in electronics and semiconductor manufacturing.

Enhancing Workforce Cyber Resilience

Enhancing Workforce Cyber Resilience Solidifying America’s Railway Infrastructure

Solidifying America’s Railway Infrastructure Remote Estimation of Above Ground Forest Biomass

Remote Estimation of Above Ground Forest Biomass Enhancing Bridges’ Structural Integrity Assessment Through Non-Destructive Evaluation

Enhancing Bridges’ Structural Integrity Assessment Through Non-Destructive Evaluation Implementing Lifecycle Characterization of Embedded Dam Gate Anchorage Using Non-Destructive Testing and Structural Health Monitoring

Implementing Lifecycle Characterization of Embedded Dam Gate Anchorage Using Non-Destructive Testing and Structural Health Monitoring Blood-Based RNA Biomarkers of Alzheimer’s Disease and Related Dementia

Blood-Based RNA Biomarkers of Alzheimer’s Disease and Related Dementia Multi Projects

Multi Projects Implant Fabrication Using Advanced Manufacturing Techniques for Bone Tissue Engineering

Implant Fabrication Using Advanced Manufacturing Techniques for Bone Tissue Engineering  The Investigation of Aerosol Formation, Transport, and Deposition in (AJP) for High-Resolution Fabrication of Electronic Devices

The Investigation of Aerosol Formation, Transport, and Deposition in (AJP) for High-Resolution Fabrication of Electronic Devices