Friday, April 19, 2013

[social_share/]

HUNTINGTON, W.Va. – Two Marshall University professors have received a second patent for an invention they say will make inspection of railroad tracks safer, more accurate and less expensive than current methods.

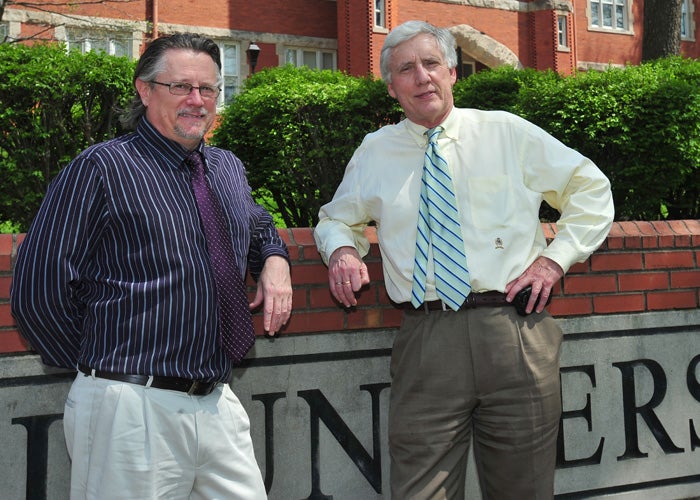

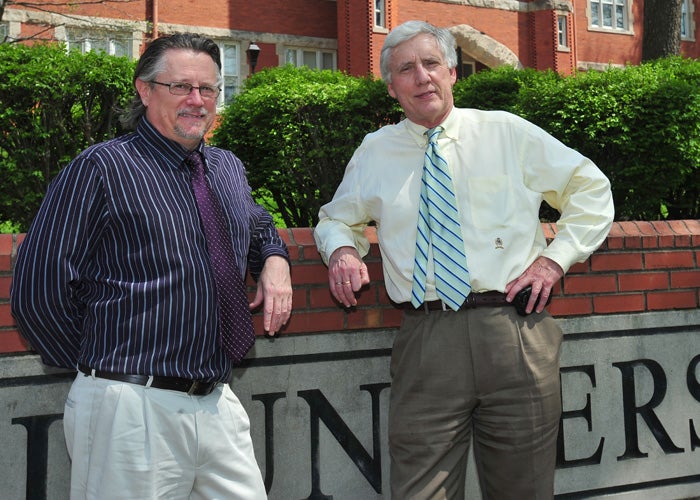

Engineering professors Dr. Richard Begley and Dr. Tony Szwilski recently were notified that their Canadian patent application has been approved. It is the first Canadian patent awarded for an invention developed at Marshall. They were awarded a U.S. patent last year.

Their system, which uses a combination of GPS devices, cameras and ground penetrating radar to measure track wear and other problems, has taken more than 10 years to develop.

Currently, they say, track inspectors have to rely largely on a limited number of multi-million dollar inspection machines that are only available to inspect the tracks a few times a year. These inspections are used in combination with bi-weekly visual observations, which must be obtained by foot in some cases.

Begley said, “Track inspection the way it’s done today is a highly specialized skill. It is labor intensive and very physically demanding. It can also be quite dangerous.”

The researchers say the invention is intended to complement the visual inspections and should help inspectors identify problems faster.

Although the components are readily available, the inventors are quick to point out that the GPS system in their device is a specialized type, not the typical navigation system found on mobile phones or in passenger vehicles.Their device uses basic “off-the-shelf” components wired together and mounted on a mobile platform that fits snugly on the rail. The platform is attached to a sports utility vehicle or rail bike adapted to run on the tracks.

Although the components are readily available, the inventors are quick to point out that the GPS system in their device is a specialized type, not the typical navigation system found on mobile phones or in passenger vehicles.Their device uses basic “off-the-shelf” components wired together and mounted on a mobile platform that fits snugly on the rail. The platform is attached to a sports utility vehicle or rail bike adapted to run on the tracks.

“Otherwise, we used readily available equipment to build the system,” Begley added. “That makes it a relatively affordable option, so we’re pretty excited about the possibilities.”

Begley and Szwilski used federal and state funding to produce a prototype of the device, which they used for field testing in cooperation with the railroad industry. Although the system was designed specifically to monitor railroad tracks from the vehicle to which it is attached, the inventors say there may also be applications for the technology to be mounted directly onto railcars and other platforms.

Szwilski said, “We’re encouraged because this technological innovation has been industry ‘pulled’ by three major railroad companies keenly interested in applying this technology to address their specific needs. We think there’s a market.”

He and Begley are now working with Marshall’s Technology Transfer Office to identify companies that might be interested in commercializing the technology.

The researchers say the entire invention process—from the concept to receiving the patent—was enlightening in many ways, especially after legal expertise was consulted with the assistance of the Technology Transfer Office and the Marshall University Research Corporation. The attorneys provided advice throughout the patent process.

Szwilski said, “We have been very grateful for the guidance and technical support Marshall has provided us. That was a vital element in our being able to successfully patent our device.”

Begley agreed, saying he has enjoyed the journey.

“It’s been fulfilling to me because we’ve been able to expand Marshall’s intellectual property global footprint through the Canadian patent,” he said. “The Marshall University Research Corporation is a critical piece of the university’s research infrastructure and, with the new Weisberg Family Applied Engineering Complex, we’ll have our research corporation and our engineering faculty researchers under one roof, helping to produce more success stories like this. The new facility will also help us recruit full-time graduate engineering students to work with our faculty from institutions here and from other countries, as well.”

Dr. Wael Zatar, dean of the College of Engineering and Computer Sciences, said, “The real beauty of this system lies in its ability to detect track deficiencies and direct the maintenance crews to the best use of their time and limited budgets. This work by Dr. Begley and Dr. Szwilski speaks well for the kind of faculty talent and expertise we possess here in our college and at Marshall overall.”

Contact: Ginny Painter, Communications Director, Marshall University Research Corporation, 304.746.1964